Automated cooler assembly line (VW)

Our automated workplace for the manufacture of a new type of cooler = increased productivity and quality of production

Basic parameters

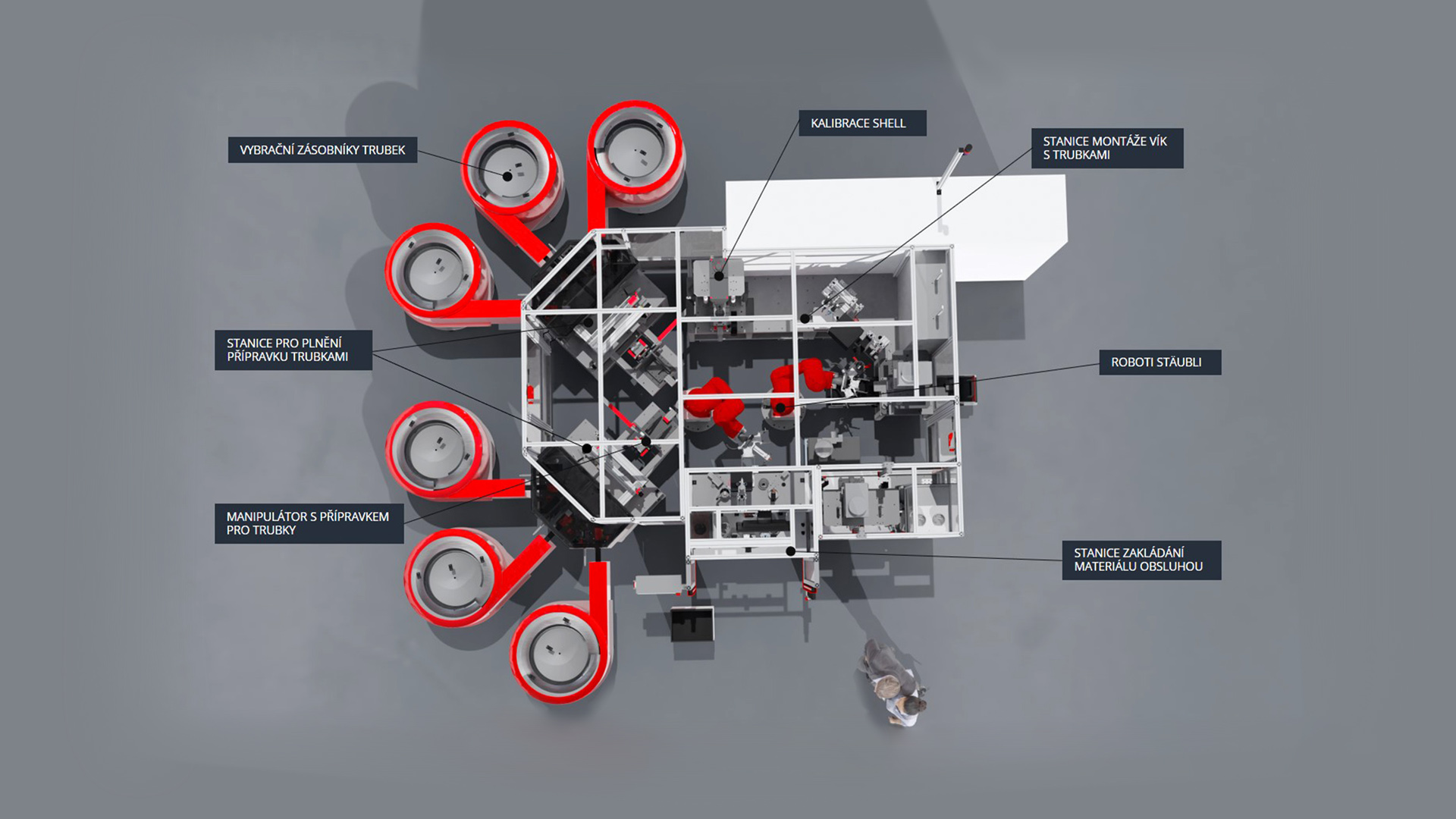

General view of the line

The robot is about to grab a part for assembly

Radiator assembly

DELIVERY OF AN AUTOMATED WORKPLACE TO ASSEMBLE THE COOLER – USING ROBOTIZATION

Name of contract: Cooler assembly for the EGR module

Term of delivery: 2018–2019

SPECIFICATION:

The customer’s main requirement was focused on increasing the quality of production, saving on manpower and increasing productivity in manufacturing a new type of cooler. Our solution is based on the delivery of several automated workplaces operated by robots.

SOLUTION – PARAMETERS:

Line cycle: 1 unit/55 sec

Capacity: 456 units/shift

DESCRIPTION OF THE AUTOMATED PROCESS:

- Inserting individual components and removing the finished product by the operator.

- Insertion, orientation and handling of tubes.

- Calibration of the outer shell – shell and partitions.

- Pasting the inner partitions of shell tubes.

- Threading and sealing tubes through the lids.

- Installing the upper and lower flanges.

- Laser marking of DMC code.

BASIC CHARACTERISTICS:

- Vibrating feeders for input parts.

- Manipulators with jigs for working with tubes.

- The parts are handled by two Stäubli robots with grippers of our own design.

- TOX pressing equipment.

- Pasting and calibration equipment.

- Laser welding equipment.

- ROFIN laser marker.

- Camera check.

- The equipment is run by one operator.

Klíčové benefity našeho řešení:

- Minimizes scrap to around 0%

- Product assembled in shorter times

- Eliminates manual inputs into the product assembly process

- Manpower savings – the device is fully automatic

- Minimizes production cycle time

- Reduces the financial costs of ensuring the assembly of the cooler